About The Author

Garry Holloway

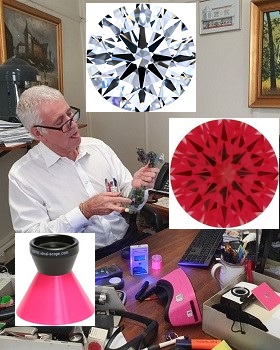

Garry Holloway is an internationally recognised diamond expert, especially concerning diamond cut quality. He has worked to improve diamond sparkle for three decades. He has invented widely used tools to identify the sparkilest diamonds.

Holloway has long believed that the industry does not correctly inspect diamonds, and he says diamond dealers spend more time looking at grading reports than stones. If they do look, it’s with a jeweler’s magnifying 10X loupe to judge the inclusions. Rarely do they use the naked eye to properly judge the diamond’s sparkle, which creates its natural beauty.

He has a BSc in Applied Geology, and Gemmological Association of Australia (GAA) diplomas of Gemmology and Diamond Technology.

Garry speaks his mind and is not afraid to challenge so-called conventional wisdom. This book is a testament to that.

Diamond ‘Cut Nut’ & Inventor

In 1996 Holloway first met Martin Rapaport, the industry famous diamond economist. Rapaport quizzed Holloways ability to estimate the angles and proportions of diamonds using just a magnifying loupe. Martin was impressed and nick-named him ‘Cut Nut’.

Garry drove his mum and dad mad with questions. Invention came easily.

In 1976, after opening his retail jewelry store, he couldn’t understand diamond pricing. Sparkle did not matter to diamond dealers; it was more about carats and clarity. That’s hardly changed.

Holloway began researching cut quality and invented cut grading tools. The Ideal-Scope was first in 1985, the Holoway Cut Adviser (HCA) in 2000. In 2018 he created Looks Like diamond size.

In this book buyers can learn how to use these tools to select the best diamonds. Sellers of well-cut diamonds can use these tools to prove the cut quality and sparkle of their stones.

Holloway contributed to the development and patenting of several widely used diamond technologies with a group of scientists and engineers from Moscow State University and Surat in India. Surat is a city where most of the world’s diamonds are cut and polished. The four were known as The Cut Group. In 2004, The Cut Group convened an International Diamond Cut Conference in Moscow and published a collection of articles.

Business Life

Holloway became a diamond jeweler by chance.

After graduating as a geologist in 1972 he took a gap year (before the concept was invented) and travelled overland from Asia to London on $1 a day. He purchased lots of gems on the way. His geology came in handy; most backpackers get ripped off with fake synthetic gems.

In London he bought some tools and began setting the gems. He became a self-taught jeweler while working as a geology assistant at University College.

On returning home to Melbourne, Australia, he took a jewelry sales assistant position and learned how to run a store. After hours and on weekends he made and sold handmade jewelry. He studied gemmology at night school.

In 1976 Garry rented a shop in an upmarket area and funded the startup by handmaking gold chains for a wholesaler as the retail business developed.

Sales grew, design awards were won. After inventing the Ideal-scope, he kept it a trade secret for 15 years, sharing scopes only with a few trusted suppliers.

The business expanded and became recognized for custom design services. At the time, it was rare for retailers to have design, gemology and jewelry manufacturing skills under one roof.

Ideal-Scope & ASET

A research project led to the invention of the Ideal-Scope, in 1984, as part of the Gemmological Association of Australia (GAA) diploma of diamond technology. The Ideal-Scope is an invaluable tool for selecting the best round cut diamonds. The International Gemological Institute (IGI) uses the Ideal-Scope as the basis of its round brilliant cut diamond light performance grading reports. The ASET scope aids in selecting the best performing fancy shaped diamonds. The book guides in the use of these instruments.

His diamond expertise saw him teach the GAA diamond diploma course in Melbourne, where he used a simplified version of the ASET scope to explain where the light seen in a diamond originated to students. He was also the national course convenor.

Thousands of both scopes have been sold around the world via Ideal-Scope.com to both consumers and the industry.

The first handheld Ideal-Scopes and an earlier version of the AGS ASET scope were based on the FireScope. Holloway received the GAA Sutherland Diamond Award for the highest marks in advanced diamond grading, theory and a research paper.

Holloway Cut Adviser – HCA

Before the year 2000 there were no effective round diamond cut grading systems, so Holloway developed and patented the world’s first in 2000. The Holloway Cut Adviser (HCA) has been used online to grade tens of millions of diamonds worth billions of dollars.

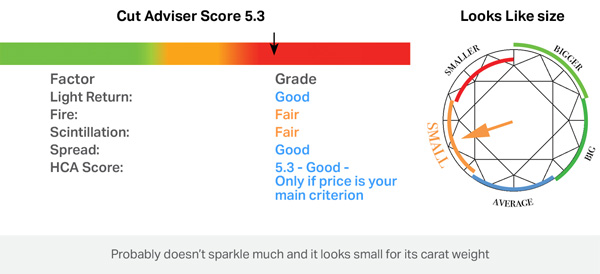

Later he patented and added a diamond size or spread estimator to HCA. The Looks Like diamond size tool predicts a diamonds apparent size relative to its carat weight.

Use HCA at www.HollowayCutAdviser.com for a small fee.

HCA is strict and rejects most GIA “XXX” top cut grade diamonds. Holloway is critical of GIA for including diamond proportions that have smaller spreads and reduced light return. This example is a diamond given three excellent grades for proportions, polish and symmetry by GIA. It scores poorly on HCA, more than 2.0, and Looks Like predicts it appears small for its carat weight. This diamond has a report or cert number 2444582428.

Discover More

Holloway Diamonds

After graduating as a geologist in 1972, and “gap Year” backpacking through Asia to London on $1 a day, buying gems, in London he bought some tools and began setting the gems in jewelry. Growing up in the house that his father built, they made all sorts of things in a well-equipped workshop. Making jewelry came easy.

Working as a Salesman

On returning to Melbourne, he thought “jewelry could be a good career”. He found a sales assistant job, learning business accounting and began copying the stock after hours. He developed a knack for making chains.

Precious Metals

He rented a small shop in Canterbury in 1976 and handmade a kilo (35oz) of gold chains for a wholesaler while growing the retail business.

Through the 80’s and 90’s

He began travelling overseas buying gold chain and hoop earrings in Italy and taught diamond polishing companies to select small stones using the Ideal-Scope (kept as a trade secret until the year 2000).

Diamonds became a larger share of our sales.

In 1998 Holloway began seriously studying diamond cut after GIA published a computer study of brilliance; their geochemists missed the obvious point.

2000’s on

Gradually the diamond cut tool businesses Ideal-Scope and Holloway Cut Adviser (HCA) grew. He became a shareholder and director of PriceScope.

In 2006 he changed the business name from Precious Metals to Holloway Diamonds reflecting the fact that diamonds made up the majority old sales.

PriceScope

In 1999, at the annual Rapaport Breakfast Briefing, Martin Rapaport showed a slide of PriceScope.com. It showed 20 different companies listing diamonds to consumers at wholesale prices. Holloway decided he needed to know more about this threat to his retail business. He contacted the owner developer and together they created a diamond tutorial. PriceScope won an industry award for that tutorial.

PriceScope, to this day, is the largest consumer diamond Forum and Garry’s is AKA the ‘Cut Nut’, the nickname given him by Martin Rapaport. Garry has helped hundreds of thousands of diamond consumers buy better-cut stones using the Holloway Cut Advisor (HCA).

The HCA has been available on the PriceScope platform for two decades and has been used to grade more than 10 million diamonds.

Videos

With a good and a bad cut diamond.

An older version, but you get the idea.

Old, a point and click camera, but easier with a smart phone.

There are other videos there – notably pink diamonds for sale

How to use the Ideal-Scope to grade diamond cut quality

Explaining 4Cs in 1 minute and showing why Cut is King

Yellow diamonds have different rules. They can cost more or less than colourless diamonds. In 6 minutes you can learn a lot and I hope it helps you choose wisely.

Using HCA – it’s been upgraded in recent years but same results. Working on creating a brand new video.

This is an 8 minute summary of most of the videos below – introduction to fluorescence in diamonds, carat weight vs size vs clarity vs cut quality.

Find out why Fluorescence in diamonds can be a benefit. Since making this video I have studied more, bought some tools, and I can see the day when good non hazy fluorescent diamonds will once again cost more, not less, than non-fluorescent diamonds.

Most people in the jewellery biz know most about clarity because they can see stuff in diamonds with a loupe. But what they do not know is that GIA uses 2 different grading systems. And sadly, size does count, and not in a good way. This is a video of less than 5 minutes and if you are interested in buying a bigger than 1ct diamond you may benefit from spending the time.

Two minutes to learn about colour, and again, why size counts in a negative way.

80% of diamonds are smaller than their carat weight indicates. Find out why in 3 minutes.

I blew the whistle on this cheating method where diamond cutters found a way to trick GIA’s cut grading system. Rapaport Magazine published an article when I alerted them.

Single & full cut 0.01ct diamond comparison in various lighting. Some prefer full and some prefer single cut. This test changed me from single cuts to full cuts.

How to show someone inclusions in a diamond using a 10X loupe.

Ever wondered why videos do not show as much sparkle as seeing a diamond with your own two eyes? 17 seconds will do it.

A client’s diamond being recut and polished to improve its light performance. You can hardly hear me because the polishing makes a lot of noise.

Planning, mapping and plotting to cut a large diamond – 2 videos

Planning a 3/4ct D Flawless round diamond from a 2.03ct rough at the hi-tech LTM factory. The operator is plotting the inclusions in the rough diamond that has had several facets polished on it to enable 3D plotting under a 120X Leica microscope that uses a patent that I co-wrote as the intellectual property. The next video follows on in the process. US 9,292,966

A one minute video showing the next part of the process in the previous video. This is a 43 carat section of an original 200ct rough diamond. The planning guys have mapped over 1,000 inclusions using patent US 9,292,966 to locate inclusions and plan the highest value diamonds by avoiding the inclusions. The operators are all engineers and physicists. The planning of this rough took a team one and a half days using half a million dollars worth of hi-tech equipment. This is probably the most advanced diamond cutting factory in the world and it is in Surat, India.